Blog detail

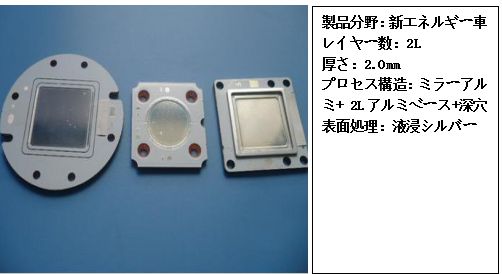

Production of thermoelectric separation copper based circuit board

Release time:

2022-07-19 00:32

Production of thermoelectric separation copper based circuit board

The production process of thermoelectric separation PCB copper substrate is as follows: cutting → baking → panel production → exposure → development → etching → panel cleaning → applying 5W adhesive → shooting → browning → gong panel → re shooting → grinding plate solder mask → exposure solder mask → character printing → forming drilling → passing through wire drawing machine → oxidation → shipment.

Usually, thermoelectric separation PCB copper substrates are used in various high-frequency circuit heat dissipation and precision communication equipment heat dissipation industries. Its thermal conductivity is many times better than aluminum and iron substrates, and it is also the most expensive metal substrate.

With the rapid development of the electronic industry in the world, the power density of products such as electronics, LEDs, smart devices, medical equipment, and new energy equipment has increased. Seeking methods for high heat dissipation and structural design has become a huge demand in today's electronic industry design. The thermal conductivity, electrical insulation performance, and mechanical processing performance of thermoelectric separation copper substrates are undoubtedly effective means to solve the problem of high heat dissipation.

The copper substrate circuit layer requires a high current carrying capacity, so thicker copper foil should be used, with a thickness generally ranging from 35 μ m to 280 μ m; The thermal insulation layer is the core technology of copper substrates. The core thermal components are composed of aluminum oxide and silicon powder, as well as polymer filled with epoxy resin. It has a low thermal resistance (0.15), excellent viscoelastic properties, and the ability to resist thermal aging, and can withstand mechanical and thermal stress. The copper substrate metal base layer is the supporting component of the copper substrate, requiring high thermal conductivity. It is generally a copper plate, suitable for conventional mechanical processing such as drilling, punching, cutting, etc. The metal layer (block) mainly plays a role in heat dissipation, shielding, coating or grounding. Due to the differences in performance between copper and aluminum and the corresponding PCB processing technology, copper substrate has more performance advantages than aluminum substrate.

Previous