Blog detail

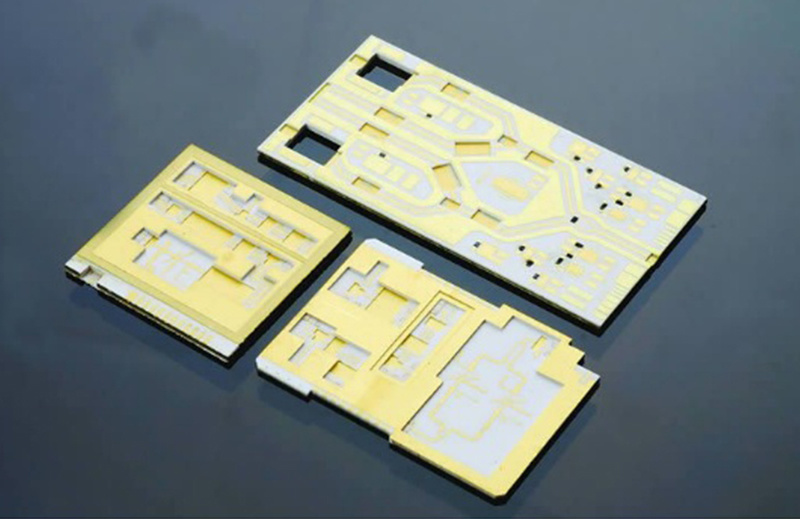

The difference between ceramic board and general PCB board

Release time:

2022-06-21 11:55

At present, the price of ceramic boards varies greatly depending on the thickness, raw materials, and production processes of the ceramic boards.

The difference between ceramic board and general PCB board

At present, the price of ceramic boards varies greatly depending on the thickness, raw materials, and production processes of the ceramic boards.

Among them, ceramic plates are divided into 92 alumina ceramic plates, 95 alumina ceramic plates, 96 alumina ceramic plates, 99 alumina ceramic plates. Of course, there are also silicon nitride ceramic plates and 99 alumina ceramic plates. The pricing of these ceramic plates is based on the thickness and specifications of the ceramic plates.

For example, a 40 * 40 * 2mm IGBT substrate costs around 3 yuan per piece. The price of aluminum nitride ceramic plates will be relatively expensive. The price of 0632 * 0.632 * 0.2mm aluminum nitride ceramics is mostly around 200 yuan. Simply speaking, the price of a PCB board with the same capacity is much more cost-effective compared to a ceramic board. Therefore, choosing a regular PCB substrate must be much more economical.

Although the raw materials used in general PCB substrates are economical, experiencing such a significant price increase is undoubtedly raising the price of corresponding products and reducing the profitability of PCB substrates.

Comparison of raw material characteristics: In general, PCB boards are made of thick cardboard, epoxy adhesive, and PC board. Except for PC board, everything else is organic. Therefore, under the irradiation of cosmic rays, chemical reactions are prone to occur, changing its chemical formula and causing deformation of the product, making it unsuitable for use in aerospace.

Compared to ceramics, general PCB substrates have lower density and lighter net weight, which is beneficial for long-distance transportation. Thick cardboard and epoxy resin board have high plasticity and are not easily broken. However, most PCB boards cannot withstand high temperatures, and the ignition point of paper is at 130 ℃, which is very low. Even with the addition of high-temperature resistant materials, its inability to withstand high temperatures cannot be changed. The ignition point of the vast majority of epoxy adhesives is around 200 ℃, and their high temperature resistance is also very weak. Finally, there is the PC board.

FR-4PC board is made by converting high temperature resistant glass fiber raw materials and high heat resistant composite materials. However, glass fiber raw materials are toxic and pose a significant threat to human health, making them unsuitable. Ceramic plates are inorganic compound products that are corrosion-resistant, high-temperature resistant, and can withstand exposure to cosmic rays. They can be used as raw materials for aerospace machinery and equipment.

The heat transfer coefficient of ceramic substrates is high, for example, the thermal conductivity of aluminum nitride ceramic plates can reach 170-230W/M.K. The heat transfer coefficient of general PCB substrates is all around 1.0W/M.K. The thermal conductivity of ceramic substrates is about 200 times that of general PCB substrates. For this type of substrate that must transfer high heat, it is undoubtedly a case of long-term drought. Ceramic substrate itself is the raw material for cable sheath, and there is no need for all cable sheath raw materials in the process of making ceramic substrate.

In the production of ceramic coated products, the bonding tensile strength between ceramic and titanium metal is relatively high, reaching up to 45MPa. Copper and ceramic metal composite materials have a better matching coefficient of thermal expansion. Under high temperature conditions, ceramic plates and metal composite material layers can be firmly bonded together, making it less likely for iron wires and ceramic plates to fall off.

Although ceramic plates are relatively brittle, they have high compressive strength and low relative permittivity in industrial equipment, making them suitable for high-frequency applications. If applied in the electronic component information industry, it can greatly reduce the signal loss rate.

Ceramic substrates are resistant to high temperatures and have a breakdown voltage of up to 2kV. In the event of sudden high voltage, it not only ensures the normal operation of the mechanical equipment itself, but also ensures the safety factor of workers.

Ceramic plates have stable physical properties and can be widely used in electronic component products that are easily corroded or require long-term washing and soaking, such as LED sensors for cars, with stable and reliable characteristics.

Overall, ceramic coated products are different from general PCB products, and they all have their own spacious living conditions in different fields. However, with market regulations, the use of ceramic coated products will become more widespread. As a new product with high-quality characteristics, it will also have more market competitiveness in the future market. The copyright belongs to the original creator. For commercial transfers, please contact the original creator for authorization. For non-commercial transfers, please indicate the source. Thank you for your cooperation. join: https://www.maigoo.com/goomai/194061.html

Previous