Blog detail

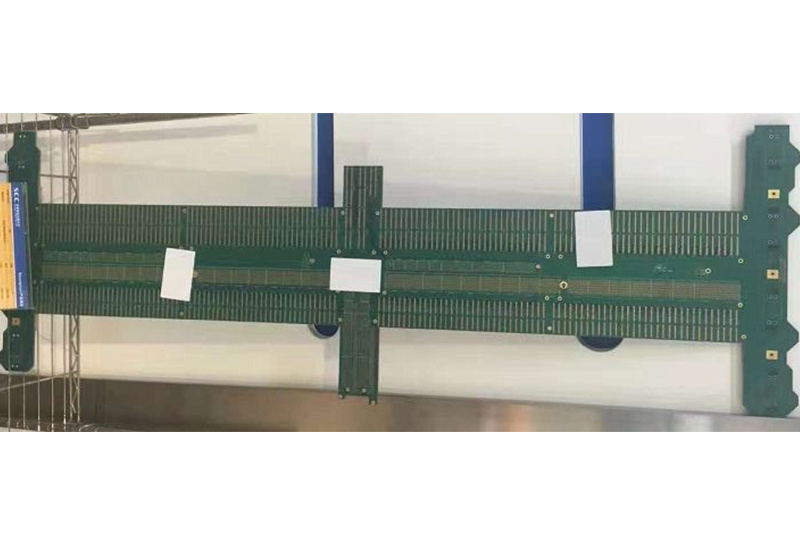

Advantages of producing large-sized printed circuit boards (PCBs)

Release time:

2022-06-21 14:08

Roll to roll drilling, roll to roll punching, roll to roll film coating, roll to roll polishing, roll to roll reinforcement machine, roll to roll electroplating, roll to roll printer, roll to roll etching line, roll to roll online AO1, roll to roll automatic punching, roll to roll fully automatic SMT (finished roll to roll achieves a specific size width of 100 meters * 1100mm, normal width of 250mm, 500mm)

Advantages of Chaosheng Group in producing ultra large size printed circuit boards (PCBs)

1、 Advantages of specialized large-sized equipment

1.1. CNC drilling machine (2600 * 1500mm)

1.2. Fully automatic screen printing machine: 2600 * 1200mm

1.3. Overall width dimension of the polishing machine: 2600 * 1200mm

1.4. Overall width dimension of electroplating tank equipment: 2600 * 1350Mm

1.5. Etching equipment width dimension: 1250mm

1.6. Effective total width dimension of compression equipment: 2180 * 1200mm

1.7. Total width dimension of laser inspection equipment: 2100mm * 1150Mm

1.8. Total width dimension of AOI equipment: 2600 * 1200mm

1.9. Total width dimension of testing machine equipment: 2600 * 1200mm

1.10, V-cut equipment width dimension "1300mm

1.11. Overall width dimension of OSPF device: 1250mm

1.12. Equipment size for the immersion gold production line: 1650 * 1150mm

1.13. Equipment size for electric nickel gold production line: 1350 * 1230Mm

1.14. Raw packaging equipment: 1600 * 1150Mm

1.15. Packaging and printing equipment size for solder paste: 2500 * 1200mm

1.16. SMT equipment width dimensions: 1700 * 1170mm;

1.17. Reflow soldering furnace equipment size: 1700 * 1150 meters

1.18. Roll to roll drilling, roll to roll punching, roll to roll film coating, roll to roll polishing, roll to roll reinforcement machine, roll to roll electroplating, roll to roll printer, roll to roll etching line, roll to roll online AO1, roll to roll automatic punching, roll to roll fully automatic SMT (finished roll to roll up to 100 meters * specific size width of 1100mm, normal width of 250mm, 500mm)

1.19. Roll to roll drilling and electroplating equipment with a width of 1.10 meters and a diameter of 100 meters;

1.20, FR-4 material specification size 2500 * 1100mm, thickness: 0.20mm to 1.0mm, copper thickness 18um to 35um

2、 Zhongjing Integrated Circuit Production Large size Double sided Panel Size

2.1: Drilling machine size: 2400 * 1100mm, can drill 2350 * 1200M meters

2.2: Fully automatic screen printing machine: 2400 * 1300mm

2.3: Optical equipment limited to double-layer size: 2600 * 1250mm

2.4: Electroplating tank equipment limited to double-layer size: 2300 * 1200mm

2.5: Total width dimension of etching processing line: 1300mm

2.6: Two layer size of compression equipment: 2180 * 1.20 meters

2.8: Anti welding single-sided spacing of 0.12mm

2.9: Minimum hole 0.50mm

2.10: Total width dimension of CNC equipment: 2600 * 1300mm

2.11: Total width dimension of the production testing machine equipment: 2500 * 1250Mm

2.12: Width dimension of V-CUT equipment "3000 * 1300mm

2.13: Overall width dimension of OSP equipment: 1250mm

2: 14: Equipment size for the gold deposition production line: 1500 * 1200mm

2.15: Equipment size for electric nickel gold production line: 1400 * 1200mm

2.16: Vacuum packaging equipment: 1300 * 1200mm

2.17: Solder paste equipment size: 2100 * 1100mm

2.18: SMT equipment width dimensions: 1600 * 1150Mm

2.19: Reflow soldering furnace equipment size: 1600 * 1150mm

2.20: Finished board thickness 0.12-10.0Mm ± 10%

2.21: Four wire test value ± 10%, size 1700 * 1200mm

2.22: E-SET 100% Test

2.23: Laser inkjet printer 2500 * 1200mm

3、 Zhongjing Integrated Production of Large Sized 4-80 Layer Buried Filler Finished Product Size

3.1. Finished size of buried holes on floors 4-80: 1350 * 1.15 meters

3.2. Finished size of buried holes on floors 10-10: 1550 * 1.15 meters

3.3. Dimensions of HDI finished products on floors 4-8: 1250 * 1150mm

3.4: Minimum line width and spacing of 7/7mil or more

3.5: Anti welding single-sided window spacing of 0.15mm

3.6: Minimum hole 0.10mm

3.7: Finished board thickness 0.25-10.0mm ± 10%