14L arbitrary order IC carrier board

FAQ Questions and Answers Q: What information is required for PCB production? CEGSATE: Gberber files for PCB production, product process instructions such as material requirements, surface treatment requirements, finished product thickness requirements, PCB stack structure diagram for advanced products, copper thickness requirements for each layer, sample quantity requirements, batch order requirements, product application fields, and other related information are required Q: What information does PCBA need to provide? CEGSATE: BOM report is required (including the brand, specifications, and model of the components), X and Y coordinate numbers of PCBA components, and processing requirements: Do we need to purchase the components on our behalf? Or customer supplied components? Do you need software burning? What is the required quantity? What is the monthly demand and other detailed information. Question: Is my file secure? CEGSATE: Your files are very secure, and we protect intellectual property rights for our clients throughout the entire process. All files provided by the customer will never be shared with any third party. Q: What is the minimum order quantity? CESGATE: There is no minimum order quantity in POE. We are able to handle small and large batches flexibly. Q: Do you have any other services? CESGATE: We mainly focus on PCB+FPC production+SMT+assembly PCBA+component procurement services; In addition, we can also provide programming, testing, software burning, wiring, and shell assembly services; And product design, product development, software development Q: What is your inspection method? How do you control the quality? CESGATE: In order to ensure the quality of PCB and FPC products, flying pin testing is usually used for samples and small batches; The inner circuit undergoes AOI optical inspection, online AOI inspection, and the finished product undergoes 100% inspection through E-SET testing rack. The appearance undergoes 100% inspection through fully automatic finished product inspection equipment and FQC. PCBA undergoes automatic optical inspection (AOI), BGA part X-Ray 100% radiographic inspection, and first article inspection (FAI). PCBA products that require software burning undergo 100% full testing through finished product testing rack according to product functional requirements

key word:

Category:

Product Description

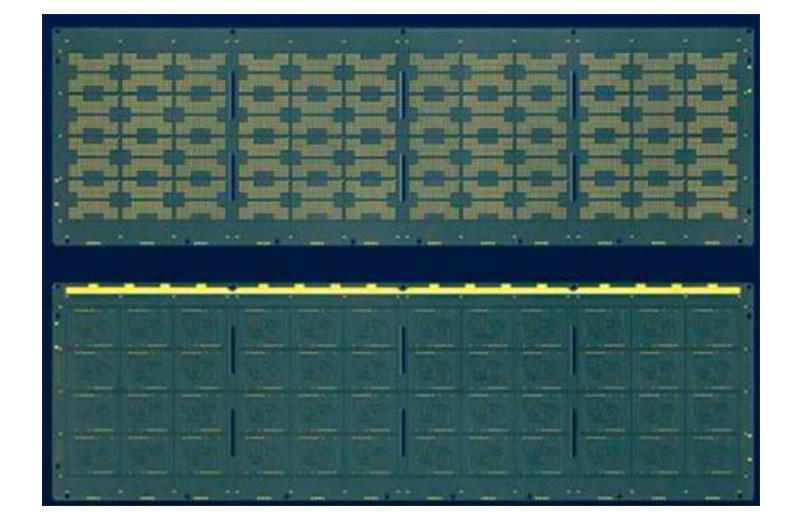

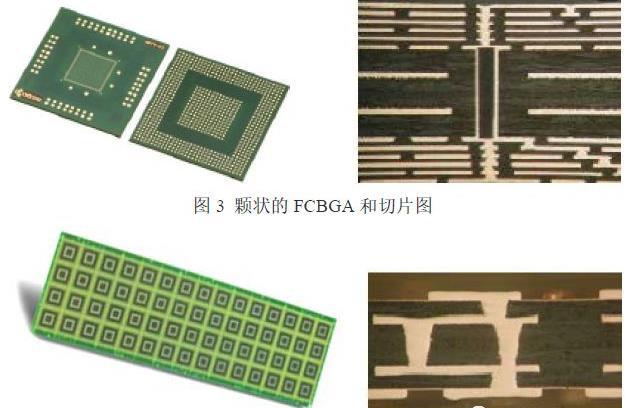

Product Application: Military IC Substrate

Layers: 14L IC carrier board of any order

Plate thickness: 0.50+10%mm

Sheet: E-705E

Minimum hole diameter: 0.20mm

Through hole/0.12mm (blind hole)

Minimum line width: inner layer 0.040mm

Minimum line width: outer layer 0.040mil

Minimum hole copper: 15um

Minimum laser hole 0.076mm

Finished copper: 1.0mil

Finished product thickness 0.50mm

Shipping size: 15*15mm (SET out)

Surface Treatment: Nickel Target Gold

Main Product Structure of Chaosheng Group Company

Production of 2-80 layer rigid circuit boards, 2-50 layer flexible circuit boards, and PCBA

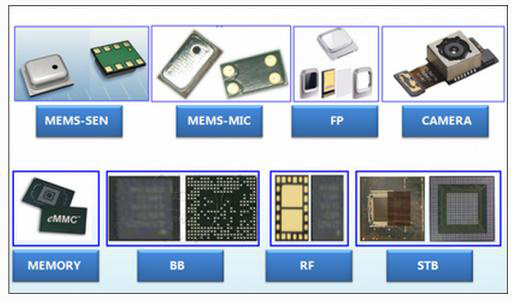

Main product categories of Chaosheng Group Company

High end double-sided, multi-layer, flexible, high-frequency, HDI arbitrary interconnection, metal substrate, high thermal conductivity metal substrate, ceramic, cut into metal substrate, cut into buried capacitor, cut into thick copper buried magnet, concave convex step substrate, 5G high-speed board, thick copper, thick gold, high carbon resistance, double-sided multi-layer MiNiLED, MiNiHDILED, MiNiOLED, IC carrier substrate, roll on roll FPC, long FPC, large-sized printed circuit board, halogen-free materials, high-frequency materials, high-speed materials Metal materials, environmentally friendly circuit boards, blind buried through-hole circuit boards, high thermal conductivity aluminum based, thermoelectric separation copper based, PDU bus, iron-based and metal based (core) hybrid boards, embedded copper buried, buried resistance and capacitance ceramic bead boards, ultra-thin BT boards, ceramic substrates, IC carrier boards, high-frequency hybrid voltage, high-speed boards, differential resistance boards, thick copper plates, thick gold-plated plates, HDI, Anylayer in any order (cross blind buried), double-sided, multi-layer, HDIFPC, soft and hard HDI, Integrated OEM and ODM production factories for roll to roll FPC, ultra long FPC, ultra large PCB production and product design and development, software development, and special material printed circuit boards.

The main application areas of PCB and PCBA products of Chaosheng Group Company

Communication terminals, communication stations, electronic communication, fiber optics, optical modules, backlights, chip systems, communication equipment, communication instruments, computers, intelligent devices, intelligent control, system control, industrial power control, industrial equipment, testing instruments, testing instruments, SD cards, SG cards, mobile phones, computers, various antennas, radars, automobiles, light sources, mold proof, music equipment, playback equipment, banking equipment, medical equipment Medical devices, medical equipment, aerospace, aviation, military, LED, OLED, OLCD power control power supply, industrial power supply, communication power supply, automotive power supply, office equipment, digital products, computers and other application fields;

The main application areas of flexible circuit boards (FPC) and FPCA products of Chaosheng Group

CompanyHard disk drives, printers, fax machines, scanners, sensors, mobile phones, connectors, modules, walkie talkie antenna cards, high-end cameras, digital cameras, laser heads, CDs, medical, instrument, driver, automotive, automotive instruments, automotive hard drives, drivers, CD drivers, medical equipment, medical equipment, LED light strips, military, aviation, aerospace, national defense and other product fields

Related products

The following is a detailed introduction about "PET carbon wire pseudo double-layer flexible FPC"

Transparent PCB, transparent flexible FPC

Detailed Introduction to Transparent FR-4 Multilayer PCB

ultra-thin ceramic circuit boards (PCBs) are like a shining star

Welcome to inquire